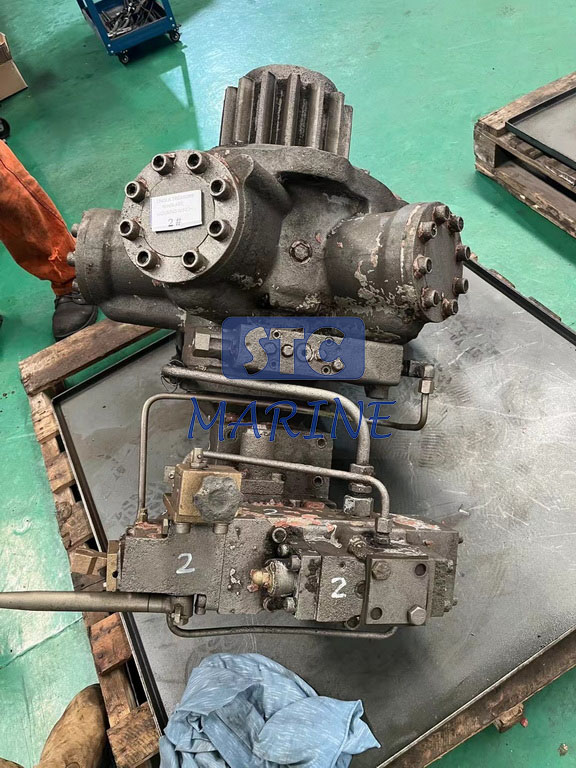

REPAIR SCOPE AND COMPATIBLE BRANDS

(1) Core Repairable Valve Block Types

- Hatch Cover Valve Blocks: TTS 2-bank/3-bank hatch cover valve blocks, MacGregor 2-bank/3-bank hatch cover valve blocks, SEOHAE side-shift hatch cover valve blocks

- Anchor Windlass/Mooring Winch Valve Blocks: HP08/HP12 series, MSCV series anchor windlass/mooring winch valve blocks

- Deck Crane Valve Blocks: CVS-32A/CVS-50A series, DC-LA-GM/DC-NS-GM deck crane control valve blocks

- Universal Valve Blocks: R5S08-59136A110152, R5V12-3933211W01A125152, DHP-32 hydraulic valve blocks

(2) Common Fault Repairs

- Corrosion Issues: Seawater corrosion on valve block surfaces, leakage caused by rusted plug-in valve plugs

- Valve Jamming: Malfunction due to worn spools of directional valves or jamming by impurities

- Seal Leakage: Hydraulic oil leakage caused by aged seals or scratched sealing surfaces

- Pressure Loss: Excessively high/low system pressure due to failed settings of relief valves or pressure reducing valves

Repair Process and Technical Advantages

-

Preliminary Evaluation:

After receiving the valve block, conduct a visual inspection (recording corrosion and leakage locations), perform pressure tests to initially identify fault points (e.g., which valve circuit is faulty), and confirm the original equipment operating conditions with the customer (e.g., rated pressure of the anchor windlass, hatch cover opening/closing speed). -

Disassembly and Cleaning:

- Disassembly: Disassemble the valve block in accordance with the original factory drawing sequence, and record the position of each valve component (plug-in valves, directional valves, relief valves) to avoid misinstallation.

- Cleaning: Remove the corrosion layer on the valve block surface via sandblasting; ultrasonically clean valve bores and spools (to eliminate oil stains and metal debris, preventing secondary jamming).

-

Inspection and Repair:

- Valve Component Inspection: Use precision measuring tools to measure the fit clearance between spools and valve bores; replace over-tolerance components with original-specification parts.

- Seal Replacement: Uniformly replace all seals; repair scratched sealing surfaces via laser cladding or precision grinding.

-

Assembly and Calibration:

- Assembly: Assemble the valve block according to original factory processes, control bolt preload (to avoid valve bore deformation), and conduct an airtightness test after assembly (to ensure no leakage).

- Calibration: Set valve block parameters on a test bench simulating ship working conditions:

- Pressure Setting: Set the opening pressure of relief valves and output pressure of pressure reducing valves (matching the requirements of anchor windlass/hatch cover systems).

- Flow Calibration: Control the flow rate of directional valves to ensure hatch cover opening/closing speed and anchor windlass chain handling speed meet original equipment standards.

-

Delivery and Documentation:

Issue a repair report (including fault causes, list of replaced parts, and calibration parameters); apply anti-corrosion paint to the valve block surface; provide installation and commissioning guidance documents.

Service Advantages

- 15 Years of Marine Experience: Engineers are familiar with the actual working conditions of anchor windlass, mooring winch, and hatch cover valve blocks, and complete over 90% of commissioning work in the workshop.

- Standardized Process: Each step—from disassembly, cleaning, and inspection to assembly—has operating standards and records, ensuring traceable repair quality.

- Accessory Guarantee: Cooperate with international valve component brands (PARKER, REXROTH) to quickly source rare valve parts, avoiding repair delays.

- Rapid Delivery: Complete standard valve block repairs within 3-5 days; handle urgent orders (e.g., ships detained for repairs) with 24-hour expedited processing, supporting air freight delivery to Shanghai/Ningbo ports.

- After-sales Guarantee: Provide a 6-month warranty after repair; if valve block faults occur due to repair issues during the warranty period, offer free re-repair and cover transportation costs.

- Technical Support: Provide remote guidance to customers on valve block installation and parameter fine-tuning via WeChat/video to resolve on-site commissioning issues.