REPAIR SCOPE AND COMPATIBLE BRANDS

(1) Core Repairable Models

- PARKER Series: T6EE 062 052 2L14 A13 M0, T6CCM B25 B20 3L03 D10M J97, T7EEC 052 052 B25 2L34 A1M0, T6C-017, GSP2-ADS13AR-A0

- REXROTH Series: A10VSO 28 DFR1/31R-PPA12N00, A10VSO 18 DFR1/31R-PPA12N00

- IHI Series: 6N67-VS, 6N57-K, HPD6-5, HPD5-5, HPD6-6

- Mitsubishi Series: MKV-11H-RFA

(2) Compatible Equipment Scenarios

- Deck Crane Hydraulic Pumps: Repair insufficient luffing/rotation power of cranes and resolve unstable lifting caused by flow fluctuations (e.g., repair of A4VG series closed-circuit pumps)

- Anchor Windlass/Mooring Winch Hydraulic Pumps: Restore system pressure and fix slow anchor chain winding/unwinding and insufficient cable tension (e.g., repair of HPD series pumps)

- Hatch Cover Power Station Hydraulic Pumps: Repair stuck hatch opening/closing and resolve hatch failure to open due to insufficient pressure (e.g., repair of A10VSO series pumps)

- Grab Hydraulic Pumps: Restore grab opening/closing power and fix grab jamming caused by unstable flow (e.g., repair of V30D-95 pumps)

REPAIR PROCESS AND TECHNICAL ADVANTAGES

Fault Diagnosis: After receiving customer feedback, obtain descriptions of pump faults (e.g., pressure value, abnormal noise location) via email/WeChat to initially determine the cause (e.g., blocked oil suction lines, worn internal seals).

-

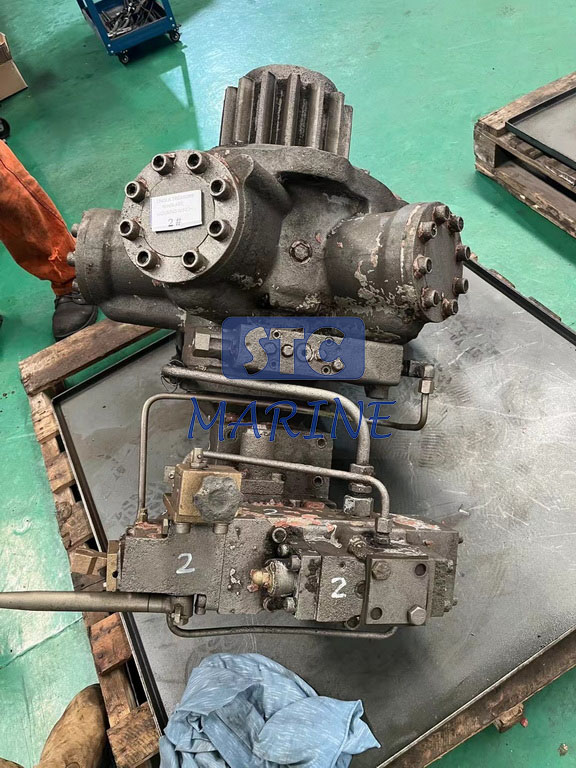

Disassembly and Inspection:

- Disassembly: Use special tools to disassemble the pump to avoid component damage, and number parts in sequence to record their positions.

- Cleaning: Ultrasonically clean all parts to remove oil stains and metal debris (with focus on cleaning valve holes and valve plates).

- Inspection: Use precision measuring tools to measure wear on key components (rotors, plungers, valve plates), and conduct pressure tests to check for housing leakage.

-

Repair and Replacement:

- Wear Repair: Use laser cladding to treat corroded/worn pump shafts, and precision boring to repair scratched valve holes.

- Accessory Replacement: Uniformly replace vulnerable parts such as seals (NOK/SKF), bearings, and springs with original-specification parts to ensure compatibility.

-

Assembly and Testing:

- Assembly: Assemble according to original factory processes, controlling preload and clearances (e.g., fit clearance between plungers and cylinder blocks).

- Testing: Simulate actual working conditions on a 160KW fully digitally controlled hydraulic pump test bench to inspect key parameters:

- Performance Parameters: Volumetric efficiency (≥90%), electro-proportional control responsiveness, stability of constant pressure/constant power control.

- Calibration Parameters: Pump zero-point calibration, pressure setting (in line with original equipment system requirements).

-

Delivery Guarantee: Issue a test report (including parameter curves), apply anti-corrosion paint to the pump surface, and provide documentation on installation precautions.

SERVICE ADVANTAGES

- Standardized Process: Adhere to ISO repair standards, with records of each operation archived to avoid quality fluctuations in traditional “experience-based” repairs.

- Accessory Guarantee: Maintain in-depth cooperation with accessory suppliers of brands like IHI, Mitsubishi, and PARKER; repair accessories arrive within 48 hours to shorten the repair cycle.

- Rapid Response: Complete standard repairs within 3-5 days, and handle urgent orders with 24-hour expedited processing.

- After-sales Support: Provide a 1-year warranty after repair; if pump failure occurs due to repair issues, offer free re-repair and cover round-trip shipping costs.