REPAIR SCOPE AND COMPATIBLE BRANDS

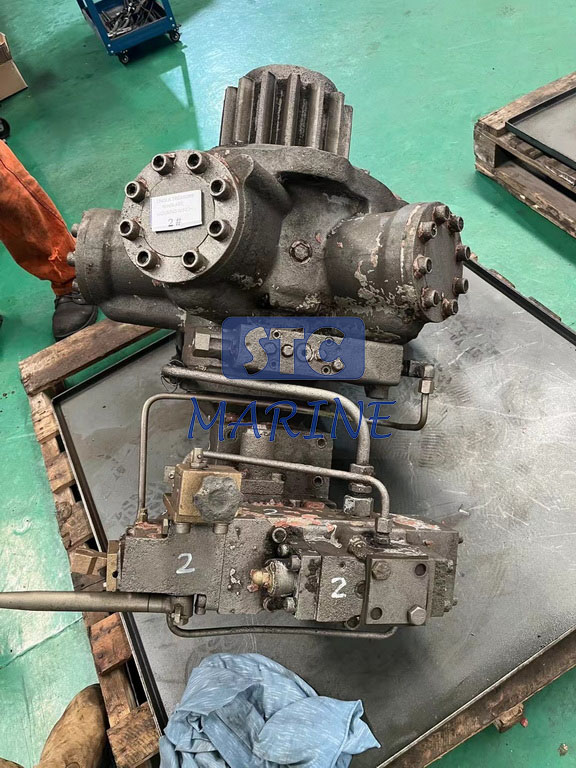

(1) Core Repairable Models

- STAFFA Series: HMC-080, HMKC080, HMC125, HMC200

- KAYABA Series: TMK-33A-M, AMC-30A-M2, HMB125

- IHI Series: MRH-750, MRH3150, MRH1500, MRH2200

- Mitsubishi Series: M2202M, MB350AS200BS091

- REXROTH Series: A6V500HD, A2F180-6.1W, A2F182L1P3

- Other Models: HVLG-DSS, HK-A, HVK-A, HVNP-DS-DC, HMKC200, HMKB200

(2) Compatible Equipment Scenarios

- Anchor Windlass Motors: Resolve issues like weak anchoring force and stuck anchor chain winding/unwinding (e.g., repair of MRH series motors)

- Mooring Winch Motors: Fix uneven cable winding/unwinding speed and severe leakage (e.g., repair of STAFFA HMC125)

- Deck Crane Motors: Restore crane rotation/luffing power and eliminate abnormal noise/vibration (e.g., repair of HMC series motors)

- Hatch Cover Drive Motors: Repair stuck hatch opening/closing and insufficient driving force (e.g., repair of GM2-3500 hydraulic motors)

REPAIR PROCESS AND TECHNICAL ADVANTAGES

-

Disassembly and Cleaning:

Use professional tools to disassemble the motor; remove surface rust via sandblasting; clean all components with ultrasonic technology (to eliminate hydraulic oil impurities and metal debris). -

Precision Inspection:

- Dimensional Inspection: Use micrometers and bore gauges to measure wear on key components (rotors, stators, oil distribution shafts); mark over-tolerance components for replacement.

- Seal Inspection: Check for aging and deformation of seals; uniformly replace all seals with original-specification parts.

- Functional Inspection: Conduct magnetic particle testing or liquid penetrant testing to identify defective areas and ensure no leakage risks.

-

Repair and Replacement:

Repair worn components via laser cladding; replace damaged parts with original or equivalent-quality accessories (e.g., bearings, springs). -

Assembly and Testing:

Assemble according to original factory processes; test under simulated actual working conditions on a professional hydraulic motor test bench:- Performance Parameters: Verify torque, speed, volumetric efficiency, and leakage (in line with original equipment technical standards).

- Control Functions: Test stability of start-stop, speed regulation, and reversing (to match actual operational needs of anchor windlasses/mooring winches).

-

Anti-Corrosion and Packaging:

Apply marine-specific anti-corrosion paint to the motor surface; use custom shockproof packaging to prevent damage during transportation.

SERVICE ADVANTAGES

- 15 Years of Experience: The team has 15 years of experience in repairing marine deck hydraulic motors, with in-depth knowledge of the structure of STAFFA, KAYABA, and other brand motors, enabling rapid identification of complex faults.

- Rapid Delivery: Standard repair cycle is 3-5 days; urgent orders (e.g., ship anchored due to anchor windlass failure) can be completed within 24 hours to align with port operation schedules.

- Quality Commitment: Repaired motors achieve over 95% of original factory performance standards; a 6-month warranty is provided, with free rework for the same fault during the warranty period.

- Technical Support: Provide Chinese-English repair reports (including inspection data and a list of replaced parts) after repair; offer on-site installation and commissioning guidance via WeChat or video calls.