COMPATIBLE BRANDS AND SERVICE CAPABILITIES

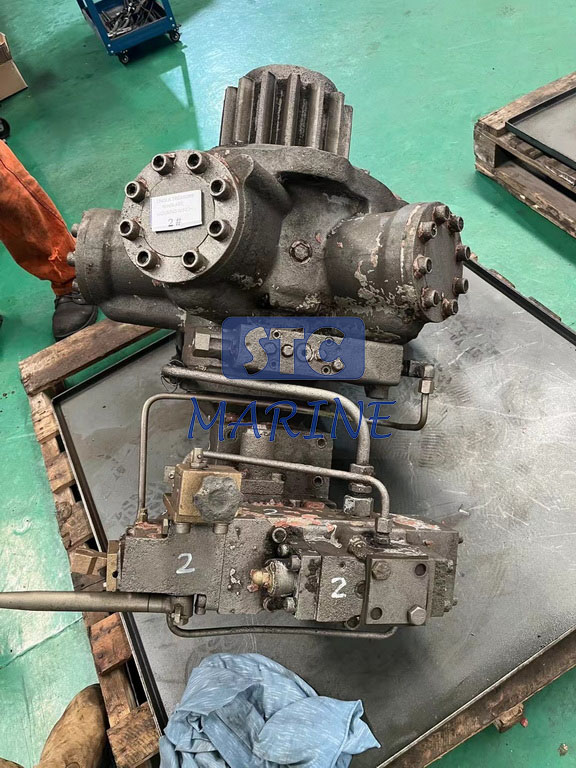

- Maintenance & Servicing Solutions: We provide sandblasting for rust removal, seal replacement, and pressure/flow calibration for valve blocks. Post-maintenance, each unit is tested under simulated real-ship operating conditions to ensure pressure and flow control precision meets the original ship’s requirements.

- Obsolete Valve Retrofit Design: When original ship valves (e.g., old-model cartridge valves, directional valves) are out of stock, we offer retrofit designs based on original parameters—reducing modification costs by 80% and delivering in 3–5 days.

- Original Drawing Production: Valve blocks are manufactured strictly following original ship drawings for TTS, MacGregor, and SEOHAE, using components from internationally renowned brands (PARKER, REXROTH, HYDAC) to ensure superior reliability and performance.

PRODUCT ADVANTAGES

- Standardized Precision Manufacturing: Processed with CNC machining centers, valve blocks achieve a hole position accuracy error of ≤0.02mm. Internal surfaces are meticulously ground to remove burrs, and all components undergo ultrasonic cleaning before assembly to prevent impurity-induced valve jamming.

- Marine-Grade Anti-Corrosion Treatment: The valve body features a nickel plating + painting finish, providing salt spray corrosion resistance of over 1000 hours.

- Complete Traceability: Production records, technical drawings, test data, and after-sales documentation are retained for each valve block, facilitating seamless customer traceability.

- 2-Hour Fault Diagnosis: Remote diagnostic solutions are provided within 2 hours of customers reporting valve block malfunctions, ensuring quick issue resolution.