REPAIR SCOPE AND TECHNICAL ADVANTAGES

(1) Core Repair Components

- Hydraulic cylinders: Piston rod surface wear, corrosion pitting, chrome plating peeling

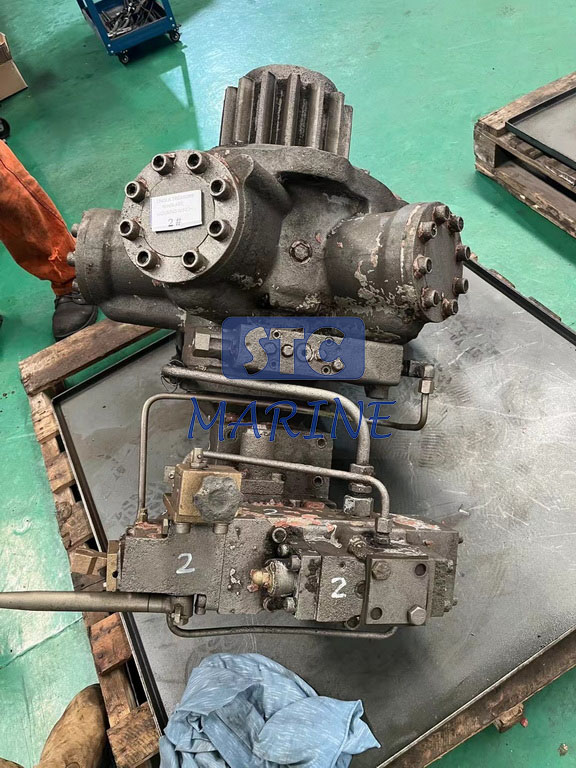

- Hydraulic pumps/motors: Pump shaft wear, motor shaft keyway damage, bearing position corrosion

- Other components: Crane sheave shaft wear, windlass/winch drive shaft corrosion

(2) Key Technical Advantages

- High-precision repair: Thermal deformation < 0.01mm, post-repair dimensional accuracy error ≤ 0.02mm, enabling direct installation without secondary processing

- Superior durability: Cladding layer bonding strength ≥ 50MPa, corrosion resistance 3-5 times higher than original components, service life reaching over 90% of new parts

- Cost efficiency: Repair cost 60% lower than replacing with new parts, repair time 80% less than traditional chrome plating (e.g., piston rod repair for an ocean-going cargo ship takes only 48 hours)

- Material compatibility: Supports various cladding materials including stainless steel, nickel-based alloys, and cobalt-based alloys, suitable for high-salt spray and high-corrosion marine environments

REPAIR PROCESS AND QUALITY ASSURANCE

- Preliminary inspection: Use precision measuring tools (micrometers, roughness testers) to measure component wear/corrosion depth, and take high-definition images for customer confirmation

- Surface pretreatment: Remove oil and rust from component surfaces through sandblasting and ultrasonic cleaning to ensure strong bonding of the cladding layer

- Laser cladding: Set laser power (1-5kW) according to component material and damage degree for precise cladding

- Post-treatment: Perform machining and dimensional calibration after cladding to ensure components meet original equipment installation standards

- Quality inspection: Verify cladding layer quality through penetrant testing (PT) and hardness testing (HRC), and provide inspection reports for customer filing

SERVICE ADVANTAGES

- Rapid response: Provide repair solutions within 2 hours of receiving customer requests

- After-sales guarantee: 6-month warranty for laser-clad repaired components