KEY FEATURES

- High load-bearing capacity: Manufactured from high-strength alloy steel or forged steel, undergoing precision machining and heat treatment (quenching, tempering) to withstand heavy loads and impact forces.

- Wear-resistant & low-friction: Sheave grooves are precision ground and often treated with hard chrome plating or laser cladding to reduce rope wear and ensure smooth rope movement.

- Corrosion resistance: Surface treated with marine-grade anti-corrosion paint or hot-dip galvanizing to resist salt spray, humidity, and port dust in harsh marine/port environments.

- Customizable design: Available in various diameters, groove numbers (single-groove, multi-groove), and installation structures (fixed, floating) to match different grab models and rope specifications.

ADAPTATION ADVANTAGES IN THE MARINE FIELD

- Grab brand compatibility: Fully compatible with international grab brands such as SMAG, TTS, and MacGregor, as well as domestic hydraulic grabs, supporting direct replacement of original parts.

- Reliable operation in harsh conditions: Optimized structural design minimizes vibration and noise during high-speed, heavy-load operation, ensuring stable performance even in rough sea conditions or busy port workflows.

PRODUCT RANGE

Our comprehensive SMAG grab accessory portfolio includes the following categories, with regular items in stock and shipped within 8 hours of ordering:

- Winch Accessories: Electromagnetic brakes, collector rings

- Drive Components: KFM cable winches, KSM guy wire winches, 200L-4 electric motors, turbo hydraulic couplings

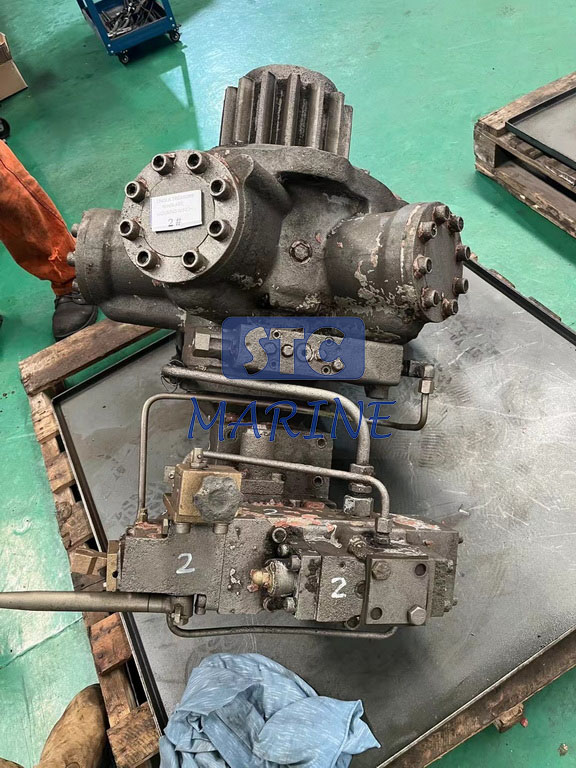

- Hydraulic Components: V30D-095-BKN-L-LS-2 hydraulic pumps, AV 5358 control blocks, hydraulic cylinders (for electro-hydraulic and remote-controlled grabs)

- Connection Parts: UW-SEE cable plug connections, mounted plug connections, various pins and wear sleeves

- Return Filters: E453-278 R11/2 return filters

- Guide Components: URN/LRN deflection and guide sheaves

PRODUCT ADVANTAGES

- 100% OEM Compatibility: All accessories match original SMAG grabs in both compatibility and performance, enabling direct replacement without system adjustments.

- Fast Delivery Turnaround: Regular accessories are shipped within 8 hours of order confirmation, minimizing operational downtime for port bulk cargo handling equipment.

- Integrated Kit Options: Offers hydraulic system kits and maintenance kits, covering all necessary parts for efficient repairs or upgrades.

- After-Sales Assurance: Provides professional installation guidance, troubleshooting support, and a 6-month warranty for peace of mind.