PRODUCT ADVANTAGES

- Standardized Precision Production: Valve blocks are manufactured via CNC machining centers, boasting a hole position accuracy error of ≤0.02mm. Internal surfaces are finely ground to eliminate burrs, and all components undergo ultrasonic cleaning prior to assembly—preventing valve jamming caused by debris.

- Corrosion-Resistant Surface Treatment: The valve body features a dual-layer finish of nickel plating + painting, achieving salt spray corrosion resistance exceeding 1000 hours for reliable marine service.

- End-to-End Traceability: Comprehensive data—including production records, technical drawings, test results, and after-sales logs—is retained for each valve block, enabling seamless customer traceability.

- Swift Fault Response: Remote diagnostic solutions are delivered within 2 hours of customers reporting valve block malfunctions, minimizing operational downtime.

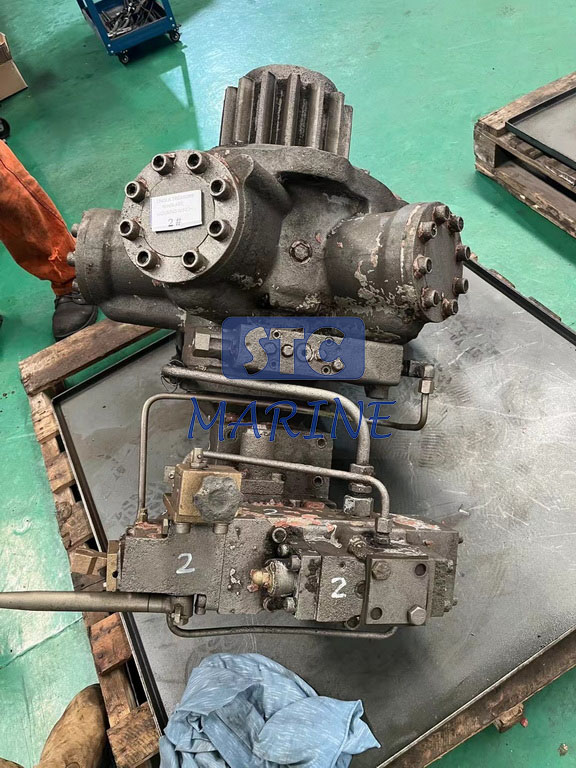

COMPATIBLE BRANDS AND SERVICE CAPABILITIES

- Original Drawing-Based Manufacturing: We produce valve blocks strictly in line with original ship drawings for brands like TTS, MacGregor, and SEOHAE. By integrating valve parts from global leading brands (PARKER, REXROTH, HYDAC), we ensure superior reliability and performance.

- Out-of-Stock Valve Retrofit: For obsolete original ship valves (e.g., old-model cartridge valves, directional valves) no longer available on the market, we provide retrofit designs based on original parameters—slashing modification costs by 80% and shortening lead times to 3–5 days.

- Maintenance & Servicing: Our services cover sandblasting for rust removal, seal replacement, and pressure/flow calibration. Post-maintenance, valve blocks undergo testing under simulated real-ship operating conditions to guarantee pressure and flow control accuracy matches the original vessel’s standards.