KEY FEATURES

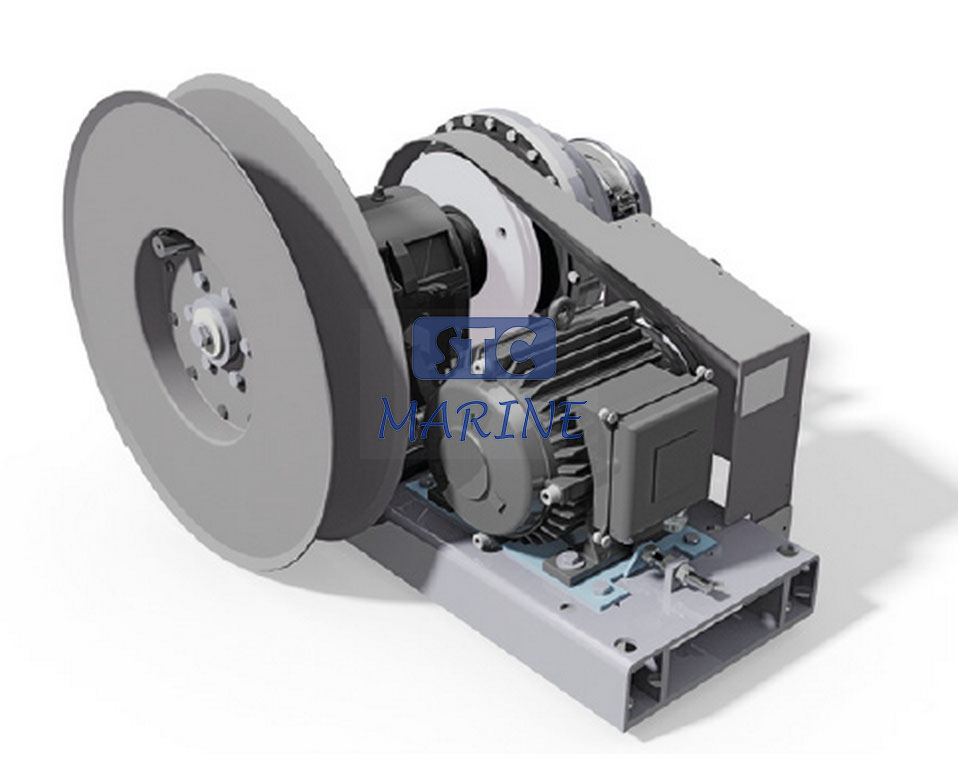

- Structural durability: Made of high-strength carbon steel or alloy steel, with precision machining and heat treatment for high load-bearing capacity and impact resistance.

- Wear-resistant design: Drum surfaces are often chrome-plated, galvanized, or coated with wear-resistant materials to reduce rope friction and prevent rust in marine environments.

- Customizable specifications: Available in various diameters, widths, and groove designs (spiral grooves, parallel grooves) to match different rope diameters, load requirements, and equipment installation spaces.

- Easy integration: Supports flange, shaft, or bracket mounting, and can be seamlessly matched with winches, cranes, and other equipment from brands like SMAG, TTS, and MacGregor.

ADAPTATION ADVANTAGES IN THE MARINE FIELD

- Marine environment resistance: Undergoes anti-corrosion treatments (such as marine-grade paint, hot-dip galvanizing) to withstand salt spray, humidity, and harsh weather conditions on ships.

- Stability in rough seas: Optimized structural design enhances stability under ship sway and vibration, preventing rope detachment or damage during extreme working conditions.

PRODUCT ADVANTAEGS

- Quick Delivery: Regular-stock SMAG grab accessories are shipped within 8 hours of ordering, ensuring that port operations experience minimal downtime.

- Full OEM Compatibility: Achieves 100% compatibility with original SMAG grabs, with performance identical to the original parts—no system modifications needed for replacement.

- Complete Kit Offerings: Provides hydraulic system kits and maintenance kits, simplifying procurement for grab system repairs or routine maintenance.

- Comprehensive After-Sales: Includes installation guidance, fault troubleshooting, and a 6-month warranty, supporting long-term reliable operation of the grab.

PRODUCT RANGE

We supply a wide variety of SMAG grab accessories, with regular items in sufficient stock. The product range is categorized as follows:

- Return Filters: E453-278 R11/2 return filters

- Guide Components: URN/LRN deflection and guide sheaves

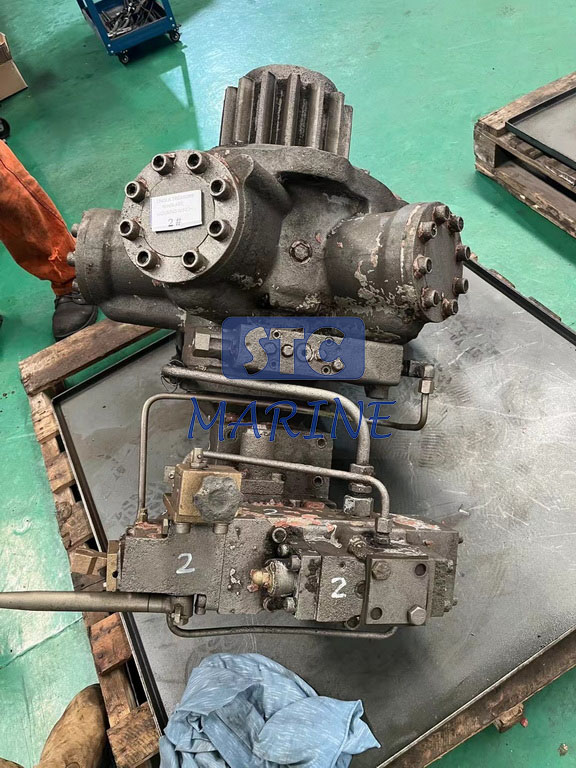

- Hydraulic Components: V30D-095-BKN-L-LS-2 hydraulic pumps, AV 5358 control blocks, hydraulic cylinders (for both electro-hydraulic and remote-controlled grabs)

- Connection Parts: UW-SEE cable plug connections, mounted plug connections, various pins and wear sleeves

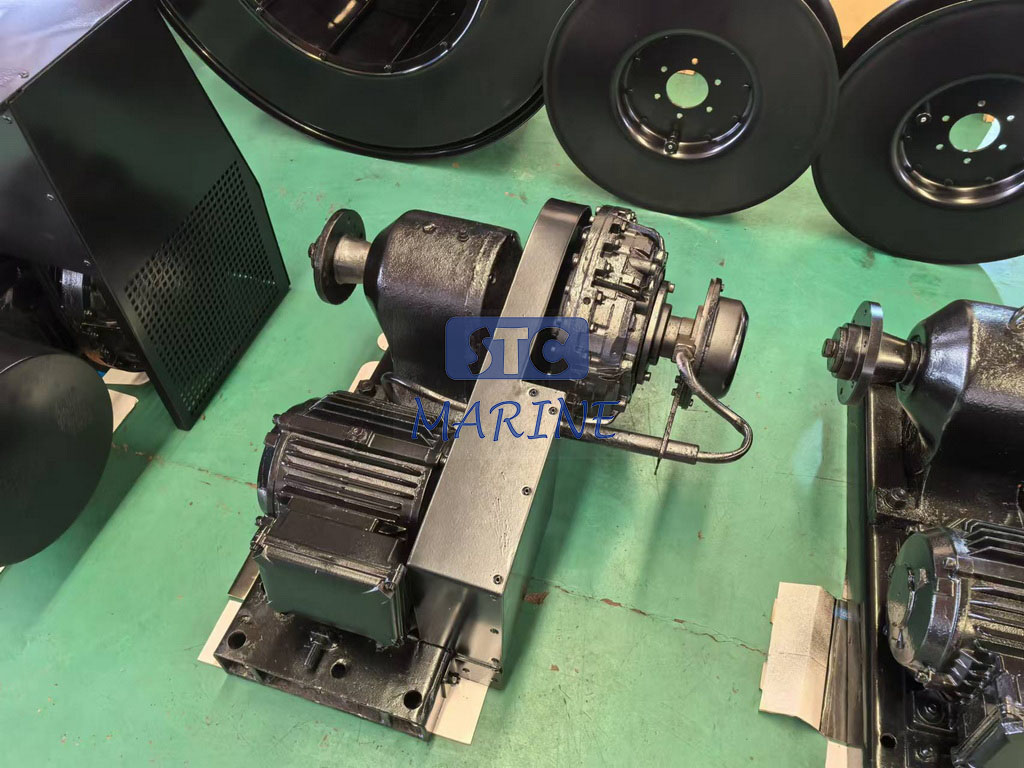

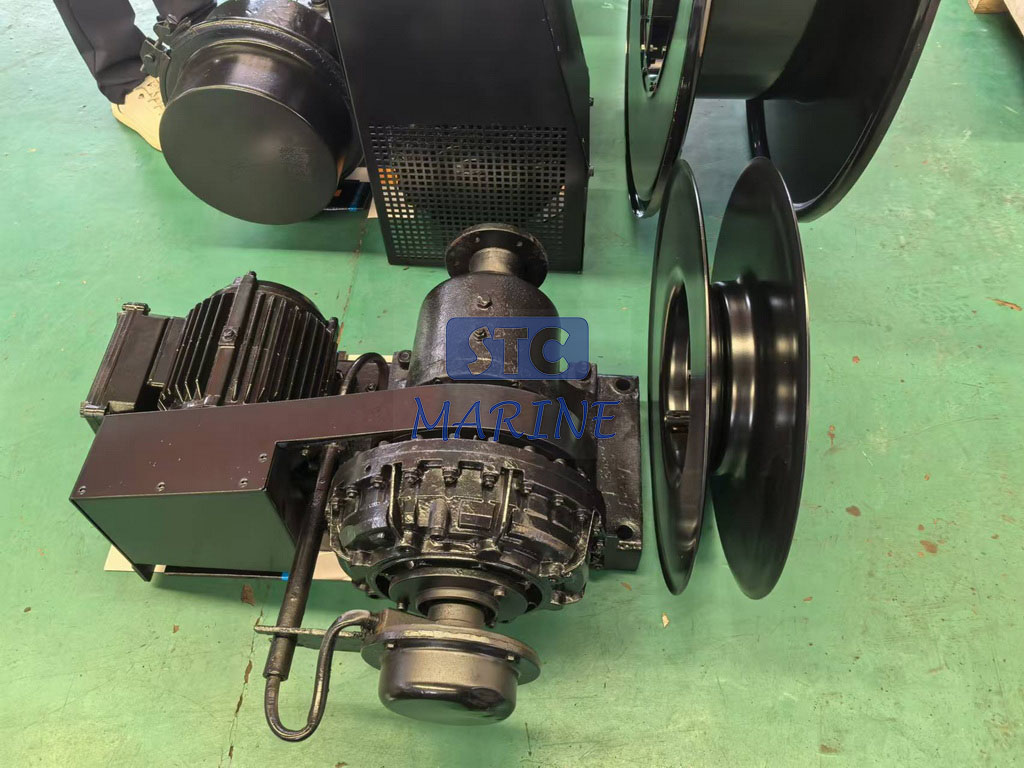

- Drive Components: KFM cable winches, KSM guy wire winches, 200L-4 electric motors, turbo hydraulic couplings

- Winch Accessories: Electromagnetic brakes, collector rings