PRODUCT ADVANTAGES

- Standardized Production Precision: Manufactured using CNC machining centers, valve blocks achieve a hole position accuracy error of ≤0.02mm. Internal surfaces are meticulously ground to eliminate burrs, and all components undergo ultrasonic cleaning pre-assembly to prevent valve jamming caused by debris.

- Marine-Grade Corrosion Resistance: The valve body features a nickel plating + painting finish, providing salt spray corrosion resistance of more than 1000 hours to withstand marine harsh conditions.

- Complete Process Tracking: Each valve block’s production records, technical drawings, test reports, and after-sales logs are retained, facilitating easy customer traceability.

- Quick Diagnostic Support: Remote diagnostic solutions are delivered within 2 hours of customers reporting valve block faults, ensuring prompt troubleshooting.

COMPATIBLE BRANDS AND SERVICE CAPABILITIES

- Obsolete Valve Retrofit: For original ship-designed valves (e.g., old cartridge valves, directional valves) no longer available on the market, we offer retrofit designs based on original parameters—reducing modification costs by 80% and shortening delivery to 3–5 days.

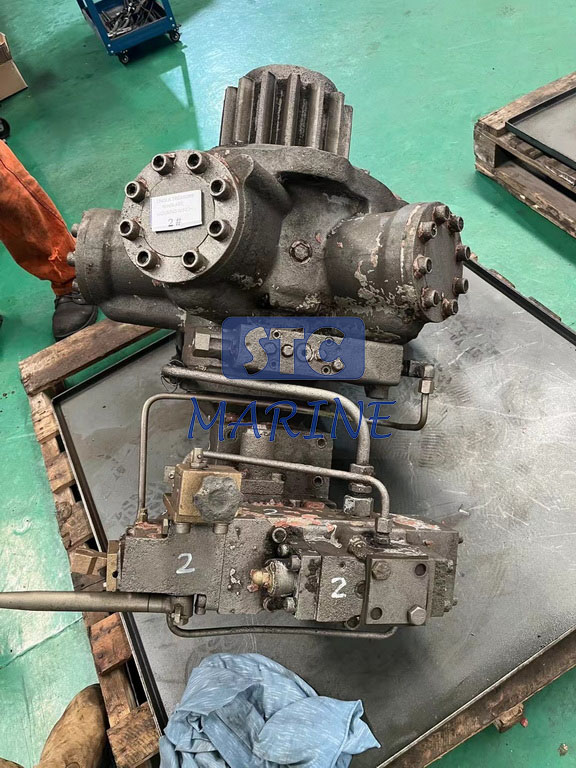

- Maintenance & Calibration: We provide sandblasting for rust removal, seal replacement, and pressure/flow calibration. Post-maintenance, valve blocks are tested under simulated real-ship operating conditions to ensure pressure and flow control accuracy matches the original vessel’s standards.

- Original Drawing Production: We produce valve blocks strictly following original ship drawings for TTS, MacGregor, and SEOHAE, using components from internationally renowned brands like PARKER, REXROTH, and HYDAC to ensure high reliability and performance.