STC MARINE ENGINEERING LIMITED

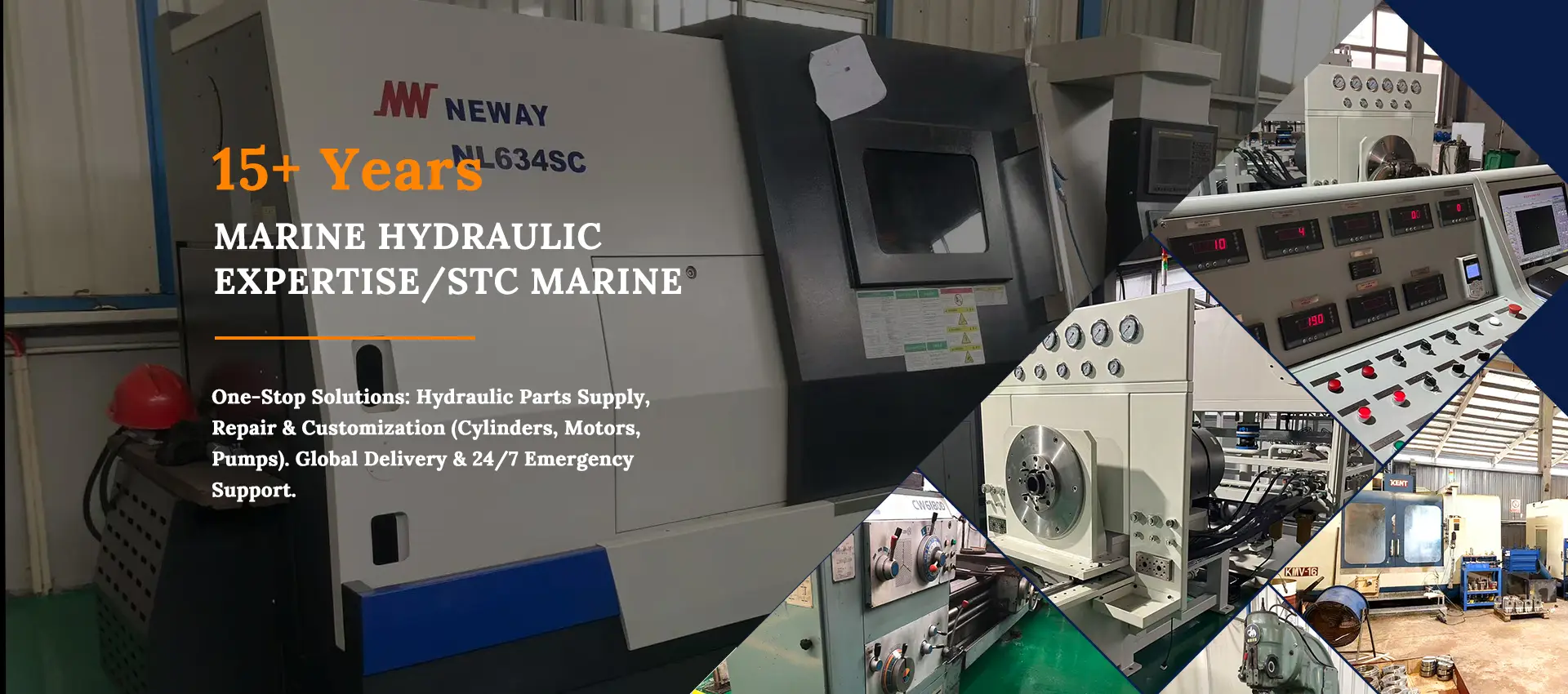

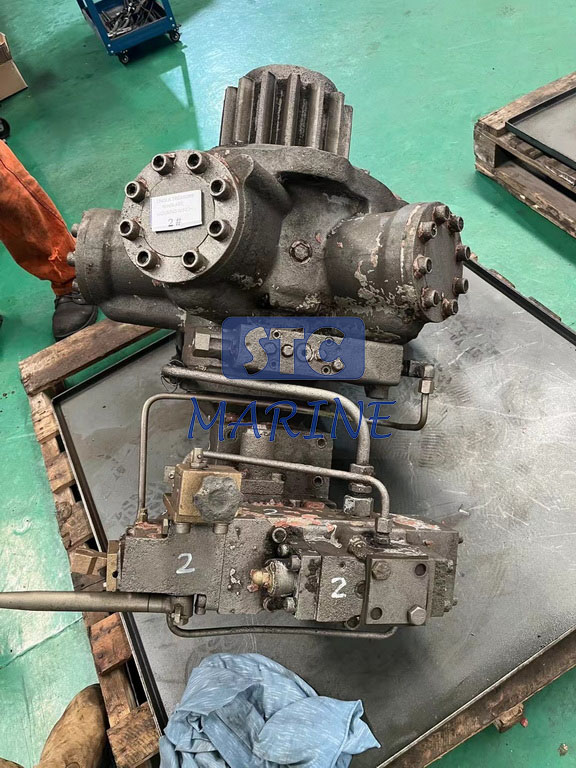

Our company mainly manufactures hydraulic cylinders for ship hatch covers, hydraulic jacks, and hydraulic control valve blocks. We also offers repair and testing services for hydraulic motors, hydraulic pumps, hydraulic cylinders, and hydraulic valve blocks.

Request For A Quotes

Contact Us

stc@shiptecmarine.com

About COmpany

Advanced equipment, professional technology, and rapid response capabilities to provide professional services for shipowners.

Our company mainly manufactures hydraulic cylinders for ship hatch covers, hydraulic jacks, and hydraulic control valve blocks. We also offers repair and testing services for hydraulic motors, hydraulic pumps, hydraulic cylinders, and hydraulic valve blocks.

Establish

STC MARINE ENGINEERING LIMITED founded in 2011

Service

We are committed to delivering high-quality products and services to our customers.

Why Choose Us

FAq

Are Always Ready To Serve

- +86 13961670091

- +86 18861659210

- stc@shiptecmarine.com

- No. 1010 Xicheng Rd, Yuecheng Town, Jiangyin City, Jiangsu Province, P.R. China

- Bulk goods: Sea freight (cost-effective).

- We accept your assigned shipping agent or can arrange via our cooperative forwarders. Nearest ports: Shanghai, Ningbo.

- 5-15 days for non-stock items, depending on quantity and customization requirements.

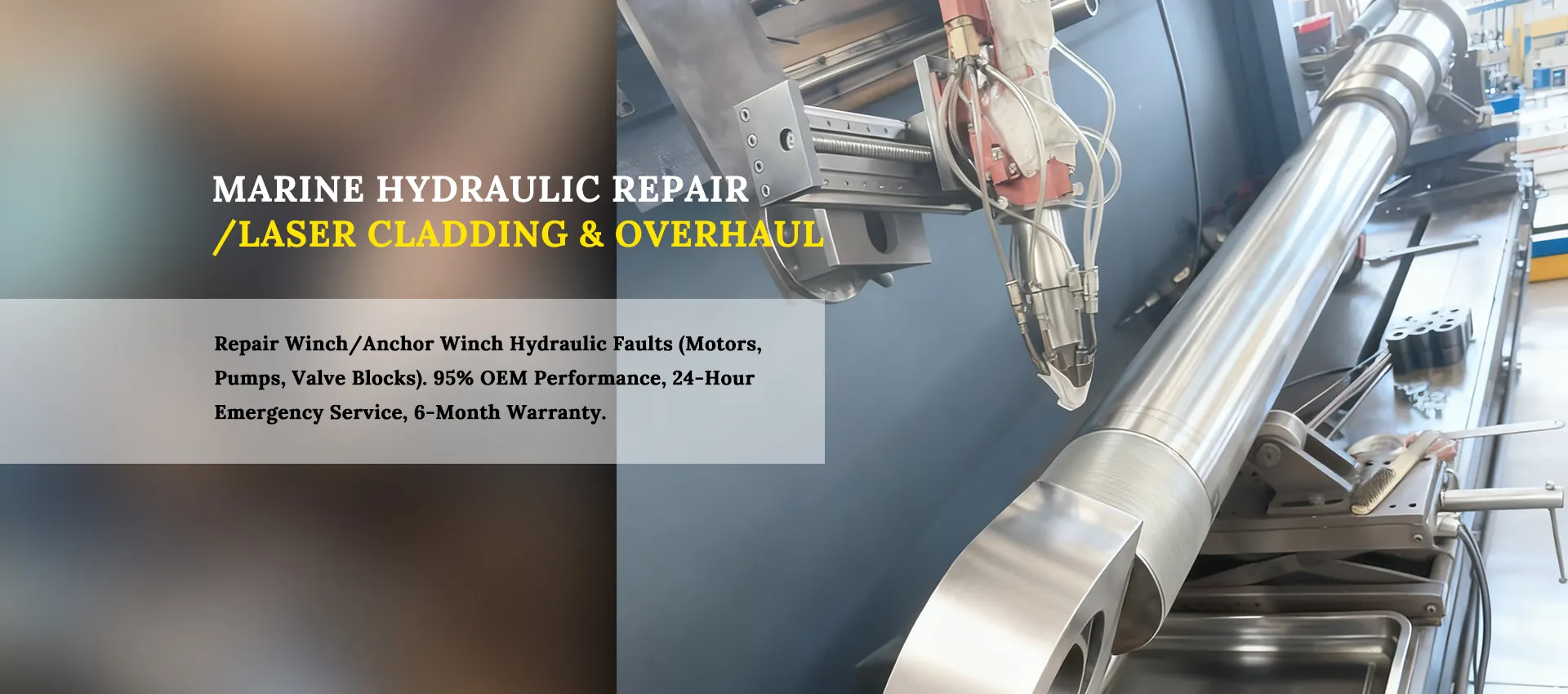

- Overhaul: Repair of hydraulic cylinders, jacks, motors, pumps, and valve blocks (including sandblasting, part replacement, testing).

- Laser cladding: Repair of worn components (e.g., piston rods, pump shafts).

- Delivery terms: EXW.

- Payment: Accepts USD, CNY via T/T.

- Language support: English and Chinese.

Our Services

Our Advantages

Exceptional Product Quality

- Pre-production: Computer-aided design and high-precision CNC machining

- Production: Hydraulic components undergo 1.5× working pressure testing and pressure holding tests

- Post-production: Performance testing on professional test benches with anti-corrosion treatments

We use seals from renowned international brands (NOK, SKF, PARKER, TECNOLAN) to ensure durability, with all products backed by a 1-year warranty.

Fast and Reliable Delivery

- Stock items (like most hatch jacks and standard sheaves): shipped within 1-2 days

- Non-stock or customized products: delivered within 5-15 days

- Emergency orders: air freight available (3-5 days to global ports via Shanghai/Ningbo)

This flexibility minimizes downtime, especially crucial for urgent situations like anchor windlass failures.

Comprehensive One-Stop Service

- Laser cladding for worn components

- On-site repairs

- Lifelong technical guidance

From pre-sales support (drawing approval, technical consultation) to after-sales assistance (remote troubleshooting, on-board repairs), we deliver seamless service throughout the product lifecycle, eliminating the need for customers to coordinate with multiple suppliers.

Experienced Professional Team

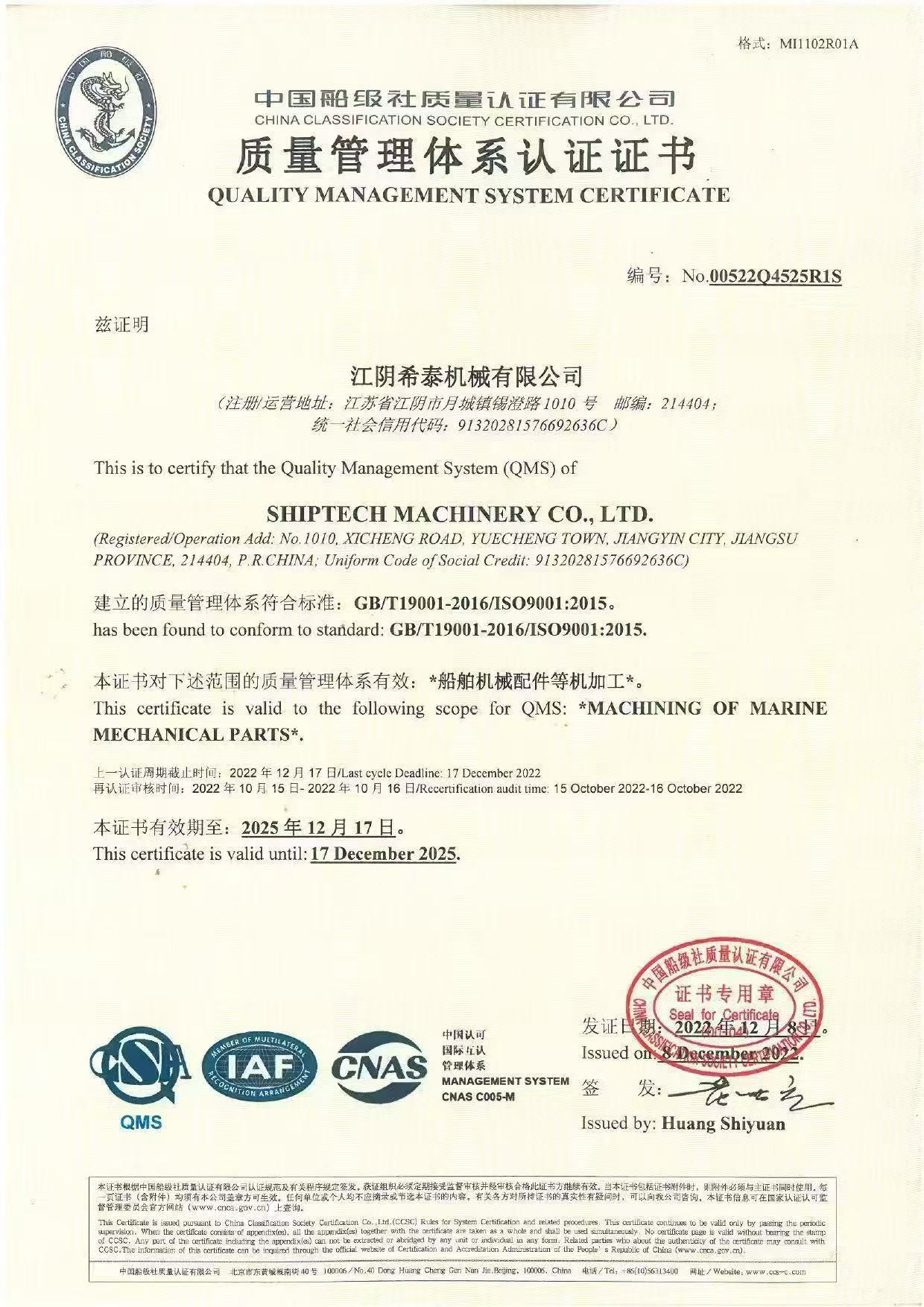

Quality Manegement System Certificate

We are certified to GB/T 19001-2016/ISO 9001:2015 for machining of marine mechanical parts (Certificate No. 0052204525R1S, valid until 17 Dec 2025), issued by China Classification Society Certification Co., Ltd. and accredited by IAF & CNAS, demonstrating our standardized quality management and enhancing customer trust in our products and services.

Rigorous Quality Assurance System

Our quality commitment spans the entire process from production and delivery to after-sales service:

- Multi-stage inspection: From raw material selection to final shipment, all components undergo ultrasonic cleaning, pressure testing, and performance verification.

- Warranty and after-sales support: New products come with a 1-year warranty (free replacement for quality issues), while repaired parts include a 6-month warranty. For installed equipment, our technical team assists with troubleshooting and provides maintenance records and inspection reports for traceability.

- Stringent repair standards: Repaired motors, pumps, and valve groups must pass simulated working condition tests, ensuring performance meets at least 95% of original equipment standards, guaranteeing reliability in harsh marine environments.

Powerful Customization Capabilities

We specialize in delivering customized solutions tailored to diverse requirements:

- Customization scope: Hydraulic cylinders (bore size 50-500+ mm) and hatch cover hydraulic control valve groups, built to customer specifications.

- Standardized process: Based on customer-provided drawings or original equipment parameters, we complete design and production within 3-14 days. Detailed manufacturing drawings are submitted for customer approval before production begins.

This flexibility ensures our products are compatible with various vessel types and equipment brands such as TTS, MacGregor, and SMAG.

CNC Machining Equipment

Hydraulic Testing and Cleaning Equipment

Ordinary Processing Equipment

Special Processing Equipment

Latest News

News & Article

What is the difference between a hydraulic cylinder and a hydraulic motor?

Abstract: Hydraulic cylinders and hydraulic motors are both fundamental components in fluid power systems; the former converts hydraulic energy into

What are Hydraulic Cylinders for Free Fall Lifeboat Davits?

Article Summary: Hydraulic Cylinders for Free Fall Lifeboat Davits play a critical role in modern marine safety systems, enabling controlled

How to calculate the size of a hydraulic cylinder?

Article Summary: Correctly estimating the volume of a hydraulic cylinder is crucial to the design of hydraulic systems; this step